Calculating the True Cost of Reactive Maintenance: What "Running to Failure" is Really Costing Your Bottom Line.

An in-depth analysis of the hidden financial and operational costs of reactive maintenance, and how modern CMMS software shifts teams to proactive strategies.

MaintainNow Team

July 30, 2025

It’s a scenario every facility manager and maintenance director knows by heart. The late-night phone call. The sudden, screeching halt of a production line. The frantic scramble to diagnose a critical failure on an HVAC unit during a heatwave. This is the world of reactive maintenance, often glamorized as "firefighting," where technicians are heroes swooping in to save the day. But the adrenaline rush and the temporary victory of getting an asset back online masks a much deeper, more corrosive problem.

For many organizations, "run-to-failure" isn't a deliberate strategy; it's a default setting. It's the path of least resistance in the face of tight budgets, understaffed teams, and the overwhelming pressure of daily operations. It feels cheaper. It feels simpler. Just fix things when they break. But this perspective is dangerously shortsighted. The true cost of this approach isn't found on a single work order invoice. It's a cascade of direct, indirect, and systemic costs that quietly bleed an organization's bottom line, erode asset value, and burn out its most valuable people. Calculating that true cost requires looking far beyond the price of a replacement part and a few hours of labor. It demands an honest accounting of what is truly being lost.

The Visible Costs: The Tip of a Very Expensive Iceberg

Let’s start with the obvious. When a critical asset fails unexpectedly, the immediate costs are easy to identify. They are the figures that show up on the P&L statement and get scrutinized by finance. But even these "obvious" costs are often significantly higher than they would be under a planned maintenance scenario.

First, there’s the labor. A planned repair is scheduled during regular hours. An emergency failure often means calling in technicians on overtime, sometimes at double-time rates or more, especially on nights, weekends, or holidays. This isn't just about the premium pay. It’s also about the disruption. The emergency pulls skilled technicians away from other important tasks—the preventive maintenance routines that were supposed to stop other failures from happening. So while one fire is being put out, the kindling is being laid for the next one. The "wrench time" on an emergency repair is also notoriously inefficient. Technicians are under immense pressure, often working without the right tools, the correct documentation, or a clear diagnosis, leading to longer repair times and a higher likelihood of mistakes.

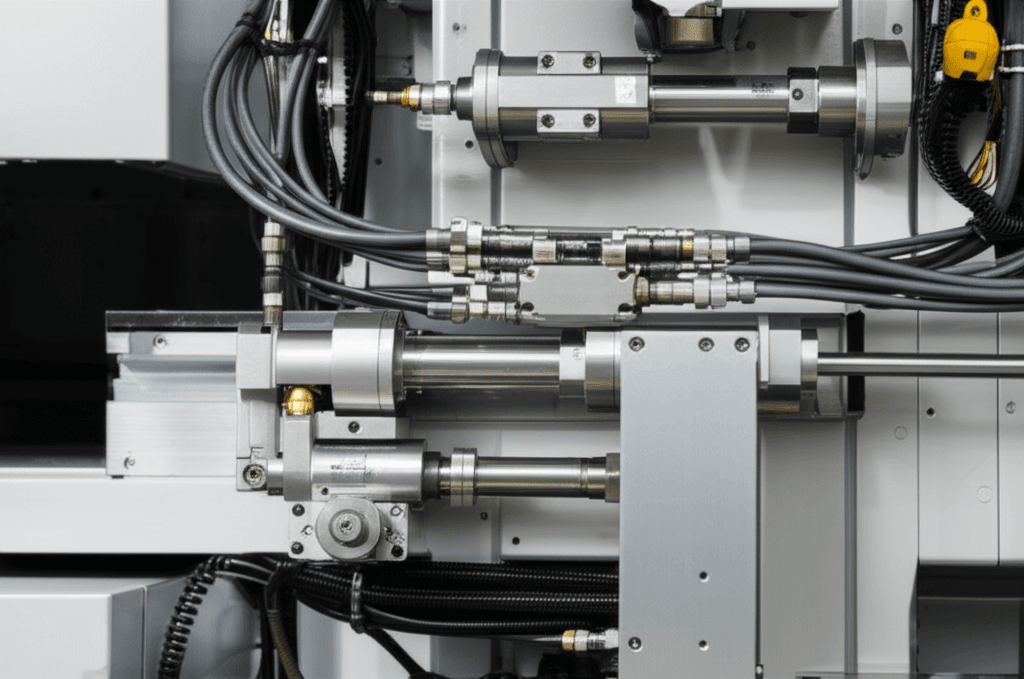

Then come the parts and materials. Need a specific VFD for a main air handler? Or a proprietary motor for a key conveyor? In an emergency, there's no time to shop around for the best price. You pay whatever the supplier with the part in stock demands, and you pay a hefty premium for expedited, overnight, or even same-day shipping. Sometimes, in a desperate bid to get operational, teams resort to cannibalizing parts from another machine—a disastrous practice that simply kicks the can down the road and creates another future failure point on a different asset.

Finally, there are the external contractor costs. If the failure involves specialized equipment—say, a complex chiller system from Trane or a sophisticated PLC from Siemens—and the in-house expertise isn't available, an emergency call to a specialist vendor is required. These contractors charge a significant premium for immediate, unscheduled service. Their travel time, diagnostic time, and repair time are all billed at emergency rates. A repair that might have cost a few thousand dollars as part of a scheduled service can easily balloon to five or ten times that amount in an emergency. These are the costs everyone sees. But they are, frankly, the smallest part of the problem. The real damage is happening just below the surface.

The Hidden Costs: Where Operational Bleeding Annihilates the Bottom Line

The financial impact that truly cripples an organization isn't on the maintenance budget; it's in the operational and business-wide consequences of the failure. These are the costs that are harder to quantify on a single invoice but have a far greater impact. Industry data consistently shows that a reactive repair is anywhere from four to ten times more expensive than the same repair performed on a planned, proactive basis. That massive multiplier comes from these hidden costs.

The most significant is unplanned downtime. What is the cost of a non-operational asset? For a manufacturing plant, it's measured in lost production units, missed shipment deadlines, and potentially steep contractual penalties for late delivery. For a distribution center, a failed conveyor system during peak season can mean thousands of delayed orders and immense customer dissatisfaction. For a commercial office building, a failed HVAC system can lead to an uninhabitable environment, forcing tenants to go home and resulting in lease-related complaints or concessions. This isn't a soft cost; it's hard revenue that is lost forever. A maintenance director needs to be able to answer the question: "What does one hour of downtime on our most critical asset cost this company?" The answer is often staggering.

Directly linked to downtime are the impacts on quality. Assets rarely fail cleanly. They often begin to degrade before the final breakdown. A CNC machine tool might start losing its tight tolerances, producing out-of-spec parts for hours before it finally seizes. A food processing line might start misaligning packages, causing product damage and waste long before a motor burns out. This leads to massive amounts of scrap, rework, and wasted raw materials. The labor and energy invested in creating those defective products is completely lost. Furthermore, the frantic rush to bring the asset back online can lead to improper setups or calibrations, extending the period of poor quality even after the initial repair is "complete."

We also cannot ignore the profound safety implications. Rushed, high-pressure emergency repairs are a recipe for accidents. Technicians may be tempted to bypass safety protocols or lockout-tagout procedures to save a few precious minutes. Makeshift, temporary fixes—the notorious "band-aid" repairs—can create new, unforeseen hazards. A failing piece of equipment is, by its nature, an unpredictable one, and it can pose a direct threat to the operators and maintenance personnel working on or around it. The cost of a single safety incident, in terms of workers' compensation, potential litigation, regulatory fines from bodies like OSHA, and damage to employee morale, can dwarf the cost of the equipment itself.

And then there's the silent killer of budgets: excess energy consumption. An asset that is struggling to perform its function consumes more energy. A motor with failing bearings, an air compressor with internal leaks, or an HVAC system with fouled coils all have to work harder—and draw more power—to achieve the same output. This is a slow, steady drain on the utility budget that often goes completely unnoticed in a reactive environment because no one is tracking asset performance over time. The gradual increase in energy draw is just accepted as the "cost of doing business" when it's actually a clear symptom of impending failure.

The Systemic Damage: How a Reactive Culture Corrodes the Entire Organization

Beyond the costs of a single failure event, a sustained culture of reactive maintenance inflicts deep, long-term damage on the entire organization. It creates a vicious cycle that is incredibly difficult to break.

Perhaps the most damaging, yet least tangible, cost is the erosion of team morale and the acceleration of employee turnover. A maintenance team that is constantly in a state of chaos, running from one fire to the next, is a team under immense stress. There is no sense of control, no opportunity for thoughtful problem-solving, and no satisfaction in a job well done—only the temporary relief of surviving another crisis. This environment leads to burnout. Your best, most skilled technicians, the ones who crave stability and want to engage in genuine improvement projects, will eventually leave for organizations that have their act together. This exacerbates the existing skills gap and leaves the team with less experience to handle the next inevitable emergency, making the cycle even worse.

This "firefighting" culture also fundamentally prevents any form of strategic thinking or maintenance planning. When 100% of the team's time is consumed by urgent, unplanned work, who has time for root cause analysis? Who has time to analyze failure trends, optimize PM schedules, or manage spare parts inventory effectively? The maintenance department becomes perpetually stuck in first gear, unable to implement the very practices that would reduce the number of emergencies. They are trapped, and the organization starts to view the maintenance team not as a strategic partner in reliability and value creation, but as an unpredictable and expensive cost center.

This directly leads to the premature death of capital assets. Running equipment to failure is the single fastest way to destroy its useful lifecycle. A commercial rooftop unit that is designed to last 20 years might only last 12 if it's subjected to catastrophic failures instead of regular, planned upkeep. Bearings that are properly lubricated can last for years; run without lubrication, they'll fail in weeks, potentially taking the motor shaft with them. This constant cycle of breakdown and major repair shortens the life of every component, accelerating the need for major capital replacement projects. The short-term "savings" of skipping a $500 PM results in a $50,000 capital expense hitting the budget years ahead of schedule.

Finally, a reactive culture creates a dangerous dependency on "tribal knowledge." In the absence of formal processes and documentation, repairs often rely on the one veteran technician who "just knows" how to fix a particular legacy machine. The fix is stored in their head, not in a central system. When that person retires, gets sick, or leaves the company, that knowledge walks out the door with them. The next time that machine fails, the team is starting from scratch, turning a manageable problem into a major crisis.

The Way Out: Embracing Proactive Maintenance Management with the Right Tools

The alternative to this chaos is not a world with zero failures. That's an unrealistic fantasy. The alternative is a world that is managed. It’s about shifting the balance of work from 80% reactive and 20% planned to the industry best-practice standard of 80% planned and 20% reactive. This shift is impossible without a fundamental change in mindset and the adoption of modern tools built for the task.

The journey starts with data. You cannot manage what you do not measure. The first step is to religiously track every single maintenance activity. What broke? Why did it break? How long did it take to fix? What parts were used? This information, when collected consistently, becomes a goldmine. It reveals trends, identifies "bad actor" assets that consume a disproportionate amount of resources, and provides the justification for moving toward a proactive strategy.

This is where a modern, capable Computerized Maintenance Management System (CMMS) becomes absolutely non-negotiable. A CMMS is the central nervous system for a successful maintenance operation. It’s the platform for effective maintenance scheduling, allowing teams to build a robust preventive maintenance program based not on guesswork, but on manufacturer recommendations, industry best practices, and, most importantly, the asset's own history. Instead of waiting for the pump to fail, the CMMS automatically generates a work order to inspect and lubricate it every three months.

Advanced CMMS software does more than just schedule PMs. It provides a complete asset lifecycle history, giving managers the data needed for long-term capital planning. It helps optimize spare parts inventory, ensuring the right parts are on hand for planned work without tying up capital in unnecessary stock. Critically, it digitizes the "tribal knowledge," storing repair procedures, schematics, and notes within the asset record, accessible to any technician at any time.

This transition is precisely what systems like MaintainNow are designed to facilitate. They provide the essential framework to move a team from a reactive posture to a proactive one. More importantly, in today's environment, this capability must be mobile. Technicians need to be able to access work orders, log their findings, and look up asset histories directly from their phone or tablet on the facility floor. Mobile CMMS access, like that provided through the MaintainNow app (accessible via app.maintainnow.app), eliminates the administrative friction of paper-based systems and ensures that data is captured accurately, in real-time, right at the source. This live data feed is the fuel for better maintenance planning and the first step toward more advanced strategies like condition monitoring. By integrating data from vibration sensors, thermal imaging, or oil analysis into the CMMS, teams can begin to predict failures before they happen, scheduling repairs at the absolute optimal moment.

The cost of running to failure is not a simple calculation. It’s the sum of overtime labor, premium parts, contractor fees, lost production, scrap and rework, safety risks, excess energy use, employee burnout, and shortened asset life. It’s a crushing, compounding weight on an organization's ability to compete and thrive. Investing in a proactive maintenance strategy, powered by disciplined processes and the right maintenance management software, is not another expense. It is the single most effective investment an organization can make to eliminate this massive, hidden drain on its profitability and operational health. It's the decision to move from being a victim of your assets to being in command of them.