Moving Beyond Preventive Maintenance: Is Your CMMS the First Step Toward a Predictive Strategy?

Explore why traditional preventive maintenance is reaching its limits and how a modern CMMS is the essential foundation for a more cost-effective predictive strategy.

MaintainNow Team

July 30, 2025

We've all been there. Standing on the plant floor or walking the rooftop, listening. Just listening. Trying to decipher the familiar symphony of whirring motors, humming transformers, and cycling compressors. We train our ears to notice the slightest change in pitch, a new rattle, a subtle vibration that wasn't there yesterday. For decades, this intuition, combined with a calendar, has been the backbone of facility maintenance. This is the world of preventive maintenance (PM), and for a long time, it was a revolutionary leap forward from the chaos of run-to-failure.

The shift to scheduled, routine maintenance tasks saved organizations fortunes. It brought a semblance of order to the inherently unpredictable world of equipment failure. Instead of waiting for a critical air handler to die on the hottest day of the year, we started replacing belts, lubricating bearings, and cleaning coils on a fixed schedule. This proactive stance undeniably extended asset life, improved safety, and gave us a framework for budgeting and planning. It professionalized the trade. We could finally put away the biggest fire extinguisher and start doing some actual maintenance planning.

But the ground is shifting. The pressures on modern facilities and industrial operations are immense. Budgets are tighter than ever. The demand for near-perfect uptime is non-negotiable. The skills gap means we have fewer seasoned experts with that trained ear, and a new generation of technicians who grew up with data at their fingertips. In this new landscape, a question is emerging in maintenance shops and boardrooms alike: Is our calendar-based PM program still the peak of efficiency, or has it become a comfortable plateau that’s actually costing us more than we realize?

The truth is, while PM was a monumental step up from reactive maintenance, it is not the final destination. It's a crucial waypoint on a longer journey. The ultimate goal is a state of near-prescience, an ability to intervene at the perfect moment—just before failure, but not a second sooner. This is the realm of predictive maintenance (PdM). And the bridge to get there, the foundational tool that makes this entire evolution possible, might already be sitting on your desktop. It’s your Computerized Maintenance Management System, or CMMS. The question is whether it's simply a digital calendar or the first step toward a truly intelligent maintenance strategy.

The Preventive Maintenance Plateau: Recognizing the Limits

Let’s give credit where it’s due. A well-run PM program is a thing of beauty. It creates rhythm. Technicians know their routes, assets get regular attention, and managers can forecast labor and parts requirements with some degree of accuracy. It helps with safety protocols, ensuring guards are in place and emergency stops are tested. Compared to the 'fix it when it breaks' mentality, it’s night and day.

But after years of running these programs, seasoned professionals start to see the cracks. We start to notice the inherent inefficiencies that are baked into the very logic of time-based maintenance. The system, for all its benefits, is fundamentally blind. It operates on the assumption that every asset degrades at the same, predictable rate. And we know, from bitter experience, that this is simply not true.

The most glaring issue is the routine practice of over-maintenance. We’ve all sent a technician to replace a perfectly good set of bearings on a motor simply because the OEM manual or our own schedule dictated it was time. That’s wasted labor, wasted material, and a direct hit to the maintenance budget. The "wrench time" is spent on a healthy asset while another, not due for service for another three months, might be quietly developing a critical fault. Worse, every time we open up a piece of equipment, we introduce risk—a seal isn't seated perfectly, a wire is nicked, a bolt is over-torqued. This phenomenon, known as "infant mortality," means sometimes our best-intentioned PM can actually induce a failure.

On the flip side of the same coin is the risk of under-maintenance, even within a robust PM schedule. A critical conveyor gearbox might be scheduled for an oil change and inspection every six months. But what if a seal fails in the second month, leading to a slow leak and lubricant starvation? The calendar is oblivious. The failure will occur long before the next scheduled PM, resulting in catastrophic gear failure, costly secondary damage, and significant production downtime. The PM schedule gave us a false sense of security. It was a check-the-box exercise that missed the real-world condition of the asset.

This "one-size-fits-all" approach is another deep-seated flaw. An organization might have two identical Trane chillers. One runs 24/7, carrying the primary load for a critical data center. The other is a redundant unit that only kicks on a few dozen times a year. A rigid PM program often treats them identically, mandating the same service intervals. This makes no logical sense. The heavily used unit is experiencing far more stress and wear, while the backup unit is being serviced unnecessarily, increasing maintenance costs for no tangible benefit. Effective maintenance planning requires nuance that a simple calendar cannot provide.

This is the preventive maintenance plateau. It’s a state of being "good enough" that prevents a team from becoming truly great. The operation feels organized, but it’s not optimized. Costs are controlled, but they’re not minimized. We're managing the passage of time, not the actual condition of our assets. To break through this plateau, we need to shift our focus from the calendar to the asset itself. We need data.

The Data-Driven Foundation: How a Modern CMMS Changes the Game

For years, many saw a CMMS as little more than a digital work order system. A way to get rid of paper requests, track who was assigned what, and close out a job. And in their early days, that's largely what they were. But the role of the CMMS in modern maintenance management has profoundly evolved. It is no longer just a system of record; it's the central nervous system of the entire maintenance operation.

A modern CMMS, and this is where platforms like MaintainNow have fundamentally altered the landscape, is designed from the ground up to be a data-gathering engine. Yes, it manages work orders, but it's how it manages them that matters. Every piece of information becomes a valuable data point. When a technician closes a work order, they aren't just clicking "complete." They're inputting failure codes, noting the cause and remedy, logging the exact parts used from inventory, and recording their labor hours. They’re adding notes, observations—the kind of "tribal knowledge" that used to walk out the door when a senior tech retired.

This is the raw material of intelligence. When this data is captured consistently and accurately across thousands of work orders, patterns begin to emerge from the noise. You can start to see that a specific model of pump from a certain manufacturer is consistently failing due to bearing seizure after 18 months in a high-temperature application. You can identify which assets are consuming the most labor hours and spare parts, giving you a clear, data-backed justification for replacement. This isn't guesswork; it's business intelligence applied to the plant floor.

The key to unlocking this potential is data quality, which has historically been the Achilles' heel of maintenance management. If the system is clunky, slow, and office-bound, technicians will take shortcuts. They’ll enter generic information, or worse, wait until the end of the day and try to recall details from memory. The data becomes unreliable, and the system's potential is wasted.

This is precisely why mobile accessibility has become a non-negotiable feature. A technician standing in front of a failed asset needs to be able to pull out a phone or tablet, scan a QR code on the machine, and instantly access its entire history. They need to be able to log parts, take a photo of the failure, and dictate notes right there on the spot. A dedicated platform like the MaintainNow app (accessible at https://www.app.maintainnow.app/) is built for this reality. It turns the point of work into the point of data capture. This seamless integration dramatically improves the accuracy and richness of the information flowing into the CMMS, transforming it from a simple database into a dynamic, living repository of asset knowledge.

This rich, detailed asset history is the true treasure. Imagine being able to look up any critical asset—an air compressor, a CNC machine, an electrical switchgear—and see a complete, chronological record of every PM, every repair, every part replaced, and every observation made throughout its entire lifecycle. This is the foundation. Without this clean, accessible, and comprehensive historical data, any move toward a more advanced strategy like predictive maintenance is simply a shot in the dark.

Bridging the Gap: From Preventive Data to Predictive Insights

So, the organization has a solid foundation. The CMMS is humming along, work orders are being managed efficiently, and a rich stream of historical data is being collected. Now what? This is where the leap to predictive maintenance becomes possible.

Predictive maintenance isn't magic, and it isn't about replacing technicians with algorithms. It's about empowering technicians with better information. At its core, PdM is a strategy of using condition-monitoring technology to assess the real-time health of an asset and predict its future failure point. Instead of asking "When was this motor last serviced?", we ask "What is the current operational health of this motor?"

The technologies that enable this are more accessible and affordable than ever.

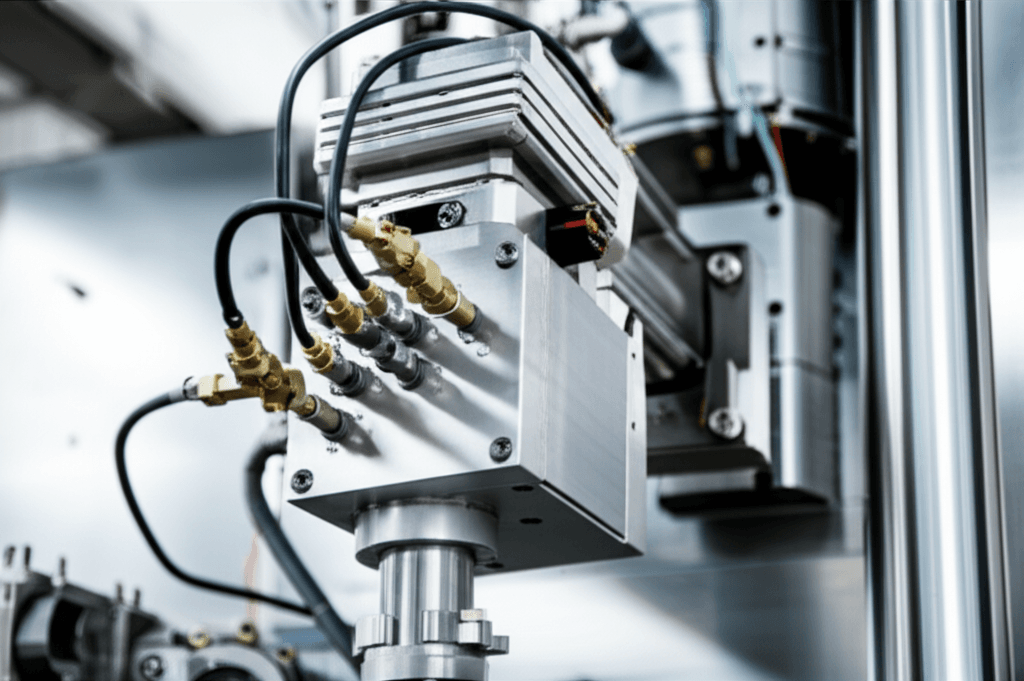

- Vibration analysis can detect minuscule imbalances in a rotating shaft or the early stages of bearing wear long before it's audible to the human ear.

- Thermal imaging can spot a loose connection in an electrical panel creating resistance and heat, a classic precursor to a fire or catastrophic failure.

- Oil analysis can reveal the presence of microscopic metal fragments or coolant in a gearbox, indicating internal wear or a failing seal.

- Ultrasonic analysis can "hear" the high-frequency hiss of a compressed air or gas leak that would be otherwise undetectable in a noisy plant environment.

For years, the problem was what to do with this data. A thermographer would take a picture of a hot breaker, write a report, and email it to the maintenance manager, where it might get lost in an inbox. A vibration analyst would provide a spreadsheet of readings, but it lived in isolation from the asset's actual service history. The condition data was disconnected from the maintenance management workflow.

This is the gap that a modern CMMS closes. It acts as the central hub where all this disparate data can converge. The CMMS asset record becomes the single source of truth. The vibration readings, the thermal images, the oil analysis reports—they are all attached directly to the specific asset's record. Now, the data has context.

The next evolution, which is already a reality for many forward-thinking organizations, is integration. A fixed sensor monitoring the vibration on a critical cooling tower fan can be programmed with upper and lower control limits. When a reading exceeds the acceptable threshold, the sensor doesn't just flash a red light; it sends an automated signal via an API to the CMMS. The CMMS, in turn, can be configured to automatically generate a high-priority work order, assign it to the correct technician, and even pre-populate it with a checklist for investigating high-vibration alerts.

This transforms the entire maintenance planning paradigm. The team is no longer reacting to a failure or blindly following a calendar. They are responding to a specific, data-driven alert about a developing problem. This allows for "just-in-time" maintenance. The shutdown is planned, but it's planned around a real need, not an arbitrary date. This surgical approach minimizes downtime, drastically reduces maintenance costs associated with unnecessary work, and optimizes the use of skilled labor.

Furthermore, this has profound implications for safety protocols. That hot breaker identified by a thermal scan is a potential arc flash event in the making. Proactively creating a work order to investigate and tighten the connection based on PdM data doesn't just prevent downtime; it prevents a potentially life-threatening incident. Having this entire process documented in the CMMS—from the initial thermal reading to the completed work order—provides an airtight audit trail for OSHA and other regulatory compliance.

The Practical Path Forward: Implementing a Forward-Thinking Maintenance Strategy

The journey from a traditional PM program to a data-driven, predictive-capable strategy can seem daunting. It’s not something that happens overnight by simply buying new software or a box of sensors. It's a cultural and operational shift that requires a deliberate, step-by-step approach.

The first and most critical step is getting the foundation right. An honest assessment of the current state of maintenance management is required. If work orders are still being tracked on spreadsheets or a legacy CMMS that technicians despise, any attempt at a more advanced strategy is doomed. The priority must be to implement a system that makes data capture easy, intuitive, and mobile-first. The goal is to establish a single source of truth for all asset and maintenance information. Without this, you are building on sand.

Once that foundational CMMS is in place, the focus should be on mastering the basics. This means achieving high user adoption, ensuring work orders are being filled out completely, building a comprehensive asset registry with proper hierarchies, and getting the PM schedules running smoothly within the new system. This phase is all about building the historical data repository. It’s about creating the baseline against which all future condition data will be compared.

Next comes the critical task of prioritization. It's a common mistake to try and apply predictive technologies to every asset in a facility. This is not only cost-prohibitive but also unnecessary. The Pareto principle is very much at play here: for most facilities, roughly 80% of downtime and maintenance costs are generated by about 20% of the assets. This is the place to start. Identify these "bad actors" and critical assets using the data now available in the CMMS. These are the prime candidates for the first phase of a PdM program.

With critical assets identified, the introduction of condition monitoring can begin—and it doesn't have to be a multi-million dollar IoT project. It can start with technician-driven rounds. Equip a maintenance tech with a handheld vibration pen or a thermal camera. Instead of just a visual inspection, their PM route now includes capturing a few key data points. These readings are then entered directly into the CMMS work order or asset record via their mobile device. This "human-as-a-sensor" approach is a powerful, low-cost way to begin collecting condition data and proving the value of the concept.

Finally, the process becomes a virtuous cycle of analysis and adaptation. With historical data and new condition data living in the same system, like MaintainNow, managers can use built-in reporting and analytics tools to connect the dots. They can see how vibration trends are correlating with eventual failures. They can use this information to adjust PM frequencies—extending them for stable assets and tightening them for those showing signs of wear. They are no longer just managing maintenance; they are actively optimizing it based on evidence. The CMMS becomes the platform not just for executing work, but for making smarter decisions about what work to do, and when.

The evolution from preventive to predictive maintenance is not about abandoning the principles that have served us well. It’s about enhancing them with intelligence. The calendar gives way to condition, and guesswork gives way to data-driven certainty. The facilities that will thrive in the coming years are the ones that recognize this shift is not a distant, futuristic concept but a practical, achievable journey. That journey doesn't start with a sensor or an algorithm. It starts with the fundamental choice of a maintenance management system that is built not just to record the past, but to actively shape a more reliable and cost-effective future. The question for every maintenance leader today is whether their current system is a stepping stone or a stumbling block on that path.