Stop Defending Your CapEx Requests. Start Proving Them with Asset Lifecycle Data.

Transform your CapEx budget meetings from defensive pleas to data-driven presentations. Learn how asset lifecycle data from a modern CMMS proves replacement needs.

MaintainNow Team

July 30, 2025

The annual budget meeting. A time-honored tradition. For many maintenance and facility directors, it feels less like a strategic planning session and more like an inquisition. The faces around the boardroom table are familiar. The CFO, sharp-penciled and skeptical. The operations chief, worried about production targets. And you, the maintenance leader, armed with a request for a six-figure capital expenditure to replace a critical piece of equipment.

The conversation is almost scripted. “Are you sure we can’t get another year out of it?” “What’s the absolute bare minimum we can spend to keep it running?” “Maintenance costs are already high, how does adding a massive capital expense help?” You’re on the back foot from the start, defending a decision that, in your professional experience, is a foregone conclusion. You know that old chiller, that aging air handler, that failing production line motor is a ticking time bomb. But “knowing” isn’t enough. Gut feelings, anecdotal evidence, and even a thick folder of repair invoices just don’t cut it in a world run by ROI and EBITDA.

The problem isn't the request. The problem is the evidence. Relying on a reactive, paper-based, or spreadsheet-driven maintenance management approach is like going into a legal battle with sticky notes as your evidence. It’s a losing proposition. The finance department speaks a different language—the language of data, of risk mitigation, of Total Cost of Ownership (TCO). To win the argument, or rather, to eliminate the argument entirely, maintenance departments must learn to speak that language fluently. And fluency comes from one place: clean, credible, and comprehensive asset lifecycle data. This is the shift from defending a budget line item to proving a business case.

The Anatomy of a Doomed CapEx Request

Let’s dissect the typical, and typically unsuccessful, capital request. It often originates from a catastrophic failure or a series of frustrating breakdowns. A primary HVAC unit goes down on the hottest day of July, or a key conveyor motor fails during a peak production shift. The immediate pain is immense. Emergency repairs, frantic calls to contractors, costly overtime for the maintenance team, and the immeasurable cost of business disruption. This is the classic run-to-failure model, and while it creates a powerful emotional argument for replacement, it’s a strategically weak position.

Why? Because it’s reactive. It frames the maintenance department as a team that only asks for money when something is on fire. The request, born of crisis, often lacks the historical context that a finance-minded executive needs to see. They see a single, large expense, not the pattern of escalating costs and increasing risk that led to this point.

The limitations of legacy tracking systems are at the heart of this failure. A spreadsheet (usually one person’s closely guarded, macro-filled masterpiece) just can't keep up. It might track total spend per month, but can it instantly show the cumulative maintenance costs, both parts and labor, for Asset #74B-1, a 15-year-old Trane rooftop unit, over the last 36 months? Can it plot the Mean Time Between Failures (MTBF) for that asset and show a clear downward trend? Can it demonstrate that the wrench time your senior, most expensive technicians are spending on that one unit has tripled, pulling them away from vital preventive maintenance on other systems?

Almost certainly not. The data is either non-existent, siloed, or so difficult to extract that it’s practically useless. This creates a state of “asset blindness.” The team knows an asset is a dog, but they can’t produce the pedigree to prove it. They can’t show the CFO a graph where the line for repair costs crosses the line for annualized replacement cost. Without that clear, data-driven inflection point, the path of least resistance for the organization is always to approve another patch, another repair, another round of kicking the can down the road. This strategy feels like saving money in the short term, but it’s an illusion. In reality, it’s just accumulating technical debt that will eventually come due with interest.

Building an Unassailable Business Case with Asset-Level Data

The way to break this cycle is to fundamentally change the conversation. It’s about moving from "We need a new one because the old one keeps breaking" to "Continuing to operate the current asset will cost the organization an estimated $75,000 more over the next two years than replacing it, not including the quantifiable risk of a multi-day outage." That second statement is built on a foundation of solid data, collected and analyzed within a modern maintenance management software platform.

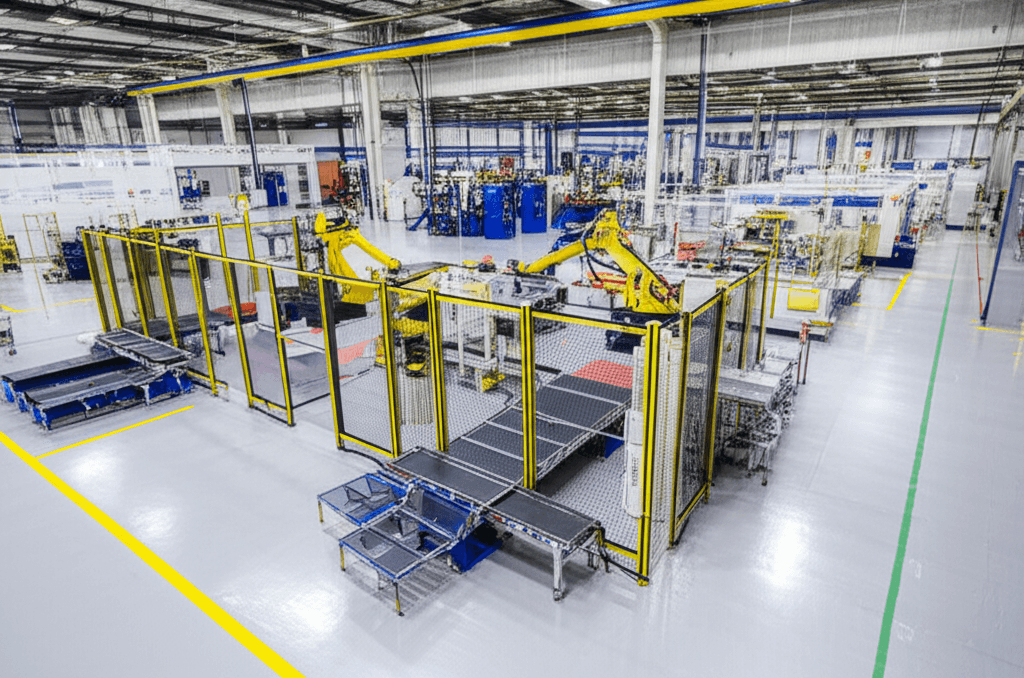

This is where a CMMS transcends being a simple work order tool and becomes a strategic asset management system. It’s about building a detailed, living biography for every critical asset in your facility. Every single action—every PM, every breakdown, every part used, every hour of labor—contributes a sentence to that biography. Over time, that biography tells a compelling story.

So, what does that story consist of? What are the data points that turn a flimsy request into an ironclad business case?

First, there’s the Total Cost of Ownership (TCO). This is the holy grail. While finance may have a record of the initial acquisition cost, they rarely have visibility into the true, ongoing cost of keeping that asset in service. A proper CMMS tracks this meticulously. It includes direct maintenance costs like the money spent on spare parts and consumables. It includes all labor, both from the internal team and external contractors, logged against specific work orders tied to that asset. This alone is often a revelation. An asset that seemed "okay" might be quietly siphoning tens of thousands of dollars a year in nickel-and-dime repairs.

But TCO goes deeper. It includes indirect costs. How much energy is that aging HVAC unit consuming compared to a new, high-efficiency model? By integrating with building automation systems or even just manual meter readings logged in the CMMS, you can quantify this. An energy-hog asset isn't just a maintenance problem; it's an operational efficiency problem. Then there's the cost of downtime. While sometimes hard to calculate, a good CMMS allows you to log downtime hours for each failure. Operations can then apply their own cost-per-hour model to that data, translating maintenance metrics into business impact. Suddenly, a four-hour outage isn't just an inconvenience; it's a $100,000 hit to the bottom line.

Second is the maintenance history itself, viewed as a narrative of decline. It’s not just about the total cost; it’s about the frequency and severity of failures. A modern CMMS like MaintainNow allows teams to categorize work orders—preventive, corrective, emergency, etc. A report showing that an asset’s work orders have shifted from 90% preventive and 10% corrective two years ago to 30% preventive and 70% corrective (with a growing number of "emergency" tags) is a powerful visual. It’s a clear indicator of declining reliability. You can chart the MTBF and watch it shrink. You can show that the average time and cost per repair are climbing, indicating that the problems are becoming more complex and severe. This data tells a story that no one can refute. It's the asset's own confession that it's reached the end of its useful life.

Finally, there’s the strategic allocation of your most valuable resource: your skilled technicians. When a veteran technician spends 15 hours in a month coaxing a legacy piece of equipment back to life, that’s 15 hours they didn’t spend performing crucial PMs on other assets. This is a hidden cost with massive ripple effects. This is how the failure of one asset can increase the risk profile of your entire facility. A CMMS that tracks labor hours per asset makes this visible. You can demonstrate to management that you're not just asking for capital to solve one problem; you're asking for capital to free up your team to prevent a dozen future problems. It’s an investment in systemic stability, not just a single asset.

The Strategic Pivot: From Reactive Firefighting to Proactive Capital Planning

Arming yourself with this level of data does more than just get a single CapEx request approved. It catalyzes a profound cultural and strategic shift within the organization. It moves the maintenance function from a perpetually reactive cost center to a proactive, strategic partner in asset management and financial planning.

This is the bridge from simple preventive maintenance to the more advanced realms of predictive maintenance and long-range capital planning. Preventive maintenance (PM) is schedule-based. We change the filter every three months, or lubricate the bearings every 500 hours of operation, regardless of the actual condition. It's a vital and effective strategy for reducing unexpected failures, and a CMMS is essential for managing these thousands of repeating tasks and ensuring compliance.

But the data collected during these PMs, and during the inevitable corrective work, is what unlocks the next level. As your CMMS database grows richer, you start to see patterns. You might notice that a specific model of pump consistently shows increased vibration readings (logged by a tech during a PM) about a month before its seals fail. This is the seed of predictive maintenance (PdM). You are no longer just reacting to failure or preventing it based on a generic schedule; you are predicting it based on the asset's actual condition and historical data. You can now schedule the seal replacement during a planned shutdown, turning a potential emergency into a routine, low-cost activity.

This predictive capability is a game-changer for maintenance costs and operational uptime. But its true power is in how it informs long-term capital planning. When you have years of rich data across hundreds or thousands of assets, you can move beyond the one-year budget cycle. You can build a credible, data-backed 5-year, 10-year, or even 15-year capital replacement plan.

Imagine sitting down with the CFO not to ask for one chiller, but to present a comprehensive "Asset Health and Replacement Roadmap." This roadmap, generated from your CMMS data, ranks every critical asset by a combination of factors: its TCO, its reliability trend, its criticality to operations, and its compliance implications. You can now say, with confidence, "Based on our analysis, the three main air handlers on Building B are our highest risk and will likely require replacement in fiscal year 2026. Following that, our primary boiler is projected to reach its end-of-life replacement window in 2028. We can begin planning and budgeting for this now to avoid surprises and secure better pricing."

This is a paradigm shift. You are no longer a firefighter. You are an asset portfolio manager. You are providing the business with the foresight it needs to manage its physical assets as intelligently as it manages its financial assets. This proactive stance is exactly what standards like ISO 55000 for asset management are designed to encourage. It’s about optimizing asset value over the entire lifecycle, and a modern CMMS is the engine that makes it possible.

The Crucial Role of Mobility and Real-Time Data

None of this strategic horsepower is possible if the data feeding the system is garbage. The old model of a technician filling out a paper work order at the end of their shift, trying to recall what parts they used and how long it took, is fundamentally broken. Data gets lost, details are forgotten, handwriting is illegible, and the information doesn't enter the system for days or weeks, if at all. This data lag and inaccuracy makes sophisticated analysis impossible.

This is where mobile maintenance isn’t just a nice-to-have feature; it’s an absolute necessity for any modern maintenance operation. When a technician has a CMMS on their phone or tablet, the dynamic changes completely. A work order is assigned, and they receive it instantly. They can walk up to an asset, scan a QR code or NFC tag, and immediately see its entire history—past work orders, manuals, safety procedures, required parts. The context is right there, in their hand.

As they perform the work, they log their time in the moment. They scan the barcode on the spare part as they pull it from inventory. They can take a photo of the failed component and attach it directly to the work order. They can record condition data like temperature or vibration readings on the spot. When they hit "complete," that clean, accurate, and rich data is instantly available in the system for the maintenance planner, the facility director, and for any analysis report.

This real-time data capture, facilitated by platforms like the MaintainNow app (accessible at app.maintainnow.app), is the bedrock of everything we've discussed. It ensures the TCO calculations are accurate. It makes the MTBF trends reliable. It guarantees that the labor hours assigned to an asset are correct. The adoption of mobile maintenance tools by the team on the floor is the single most important factor in transforming a CMMS from a simple logging tool into a powerful engine for business intelligence. It democratizes data collection and, in doing so, elevates the strategic value of the entire maintenance department.

The Final Verdict: Presenting, Not Defending

Let's return to that boardroom. But this time, it’s different. The maintenance director isn't on the defensive. They are presenting. On the screen are not just pictures of a rusty, leaking piece of equipment, but charts and graphs pulled directly from their maintenance management system.

Here is the TCO of the asset over the last three years, clearly showing an exponential rise in maintenance costs. Here is the chart of its declining MTBF, a stark visual of its failing reliability. Here is a breakdown showing that 40% of our lead technician’s time last quarter was spent on this single asset. And here is the projected cost comparison: the documented cost of continuing to repair versus the annualized cost of a new, more efficient replacement, showing a clear ROI within 30 months.

The questions from the CFO change. They're no longer "Can we get by?" They are "What’s the lead time on the new unit?" and "Does this ROI calculation account for the expected energy savings?" The conversation is now a collaborative, strategic discussion about mitigating risk and making a sound financial investment. The maintenance director is no longer seen as just a manager of costs, but as a manager of critical business assets.

This transformation is not a fantasy. It is the reality for thousands of facilities and operations that have embraced a data-first approach to maintenance management. It begins with the understanding that you cannot manage what you do not measure, and you cannot prove what you do not document. Kicking the can down the road on investing in a proper CMMS is, in itself, a costly decision—one that guarantees you will remain in a defensive posture, fighting budget battles you were destined to lose. The tools to change the narrative exist. The journey from defending requests to proving them is a journey toward operational excellence, and it starts with a commitment to leveraging your most powerful tool: your own data.